Category 1: Entry-Level Shrink Wrap Equipment

Model KRX Combination Sealer and Tunnel

Although the Seal-A-Tron Group classifies this combination unit as “Entry-Level” machinery, it is designed as an indestructible unit and has proven itself over years of multiple shift operations.

S-1620 L-Bar comes standard with our TRU Temperature seal wire controls, which prevents the need for seal wire repairs, thus offering consistent sealing throughout years of production.

The T-1910-30 shrink tunnel has airflow and constant heat that creates impeccable shrink packaging! This model comes standard with digital temperature controls and solid-state electrical relay.

Model S-1722

This L-Bar sealer offers the best of both worlds by giving the option of utilizing a TRU Temperature Hot Wire, or a Hot-Knife Sealing Blade. The Hot-Knife Sealing Blades provide additional alternatives for sealing through the use of different plastics, which include PVC and Polyethylene.

Model T-1910-30

The T 1910 shrink tunnel has airflow and constant heat that creates impeccable shrink packaging! This model comes standard with digital temperature controls, solid-state electrical relay, and adjustable height stand!

Category 2: Industrial Level Shrink Wrap Equipment

Model S 2330

Model S 3236

These standard model sealers can be accessorized to accommodate the specific needs of our customers. Some of which include the option of larger seal areas, Hot-Knife Seal Blades, Powered Film Unwinds, and Inverting Film Plows! These sealers are proven industrial production machines!

Model T 2213

T 2813, T 3613

Our standard level tunnels are recognized as leading contenders in the shrink-wrap industry, and have been the backbone of Seal-A-Tron over the years! From the heavy-duty frame design to the incredible airflow controls, these tunnels create the perfect package! In addition, the GFN Conveyor Belt allows for a virtually maintenance-free tunnel conveyor.

Category 3: Automatic L-Bar Sealer Equipment

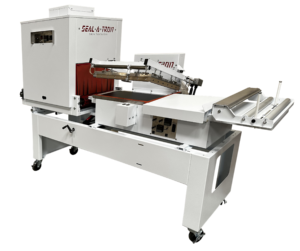

Model AS 2024 AC

The All NEW! Automatic L-Bar has what it takes to increase production and create consistent packaging!

The Electronic Seal Stroke eliminates the need for compressed air!

The machine comes equipped with many standard options, which make our unit operator-friendly. We offer variable speed controls, product staging, easy touchscreen controls, center seal adjustment, and a closing conveyor. With addition of Model T 2213 and a Special In-feed Conveyor, this has the capability to become a complete automated system that allows for more efficient packaging at an affordable investment!

Category 4: Custom Designed Shrink Wrap Equipment

Custom Designed L-Bars and Tunnels

Seal-A-Tron recognizes that there are many applications that call for special sizing and product handling, so we offer L-Bar Sealers and Shrink Tunnels that have the capability to meet the specific needs of our customers. We will design and build to our customer’s requirements!

Category 5: Poly Bundling Equipment

Model MIBP & AIBP

Both Manual In-feed and Automatic In-feed Poly Bundlers

Our goal for this design is to provide customers with an affordable Industrial Level Bundling machine. We have been able to achieve this by offering the customer an intermittent conveyor-to-conveyor sealer along with a manually fed, right angle fed, and fully inline automation design. These units are offered in a variety of sizes, please consult the factory for each application.